There is indeed plastic that is hygroscopic. TPU, for example. I didn’t feel like crafting solutions with Ikea boxes and simply ordered a set with which I can vacuum filament.

Inhalt:

Which filaments are hygroscopic?

“Hygrowhat? Always these foreign words!”. Okay, no biggie

Hygroscopic is a term used to describe materials that have the ability to absorb moisture from the surrounding air. Salt is a hygroscopic material that everyone is familiar with from the household. Water is absorbed in the form of vapour or moisture.

Better?

PVA is a filament that can absorb a lot of moisture. It can hold up to 10% of its weight in moisture. TPU also shows a high moisture absorption of up to 5% of its weight.

Nylon, PETG and ASA are also hygroscopic, but less so than PVA or TPU. Wood filaments are partially hygroscopic depending on how much wood fibre they contain. PC has the lowest hygroscopic effect in this list.

1 – PVA (polyvinyl alcohol)

PVA is a water-soluble(!) filament that is often used as an easily washable support material for dual extrusion 3D printing. PVA is biodegradable. It really should be kept properly dry!

2 – TPU (thermoplastic polyurethane)

Flexible, elastic and tough. Has excellent layer adhesion, but unfortunately TPU filament is hygroscopic.

3 – Nylon (polyamide, PA)

Nylon filament is known for its strength, toughness, and durability. It is typically used for mechanical parts, wear parts, tools, prototypes, and the like. Nylon is a … no … the typical hygroscopic filament.

4 – PET, PETG, PETT (polyethylene terephthalate )

PETG offers high strength and good weather resistance, but it is also hygroscopic and should be stored dry.

5 – ASA (Acrylonitrile Styrene Acrylate)

ASA is a filament material with similar properties to ABS, but with improved UV and weathering resistance. For example, for prints to be used in motor vehicles. It is also hygroscopic.

6 – Polycarbonate (PC)

Polycarbonate filament is known for its high strength and temperature resistance. However, it is also a hygroscopic filament.

7 – Wood filament

Filaments that contain wood particles, for example wood PLA, can also be hygroscopic. The wood fibres contained can absorb moisture, which makes the filament brittle.

Symptoms that indicate damp filament

Signs that the filament has absorbed water.

Crackling

Crackling noises during printing caused by the evaporation of moisture in the filament are a sign of vapour bubbles.

Vapour bubbles

When the wet filament is heated, this can cause bubbles or irregularities in the printed layers and surfaces. It always depends on the model whether you notice these.

Poor layer adhesion

Damp filament can lead to poor layer adhesion and thus to an unstable component. Especially with functional parts, this is fatal.

Expensive solution

Makers of the world naturally reach for one of the many filament dryers or an automatic dehydrator. Then there’s another appliance flying around the household that replaces something you have anyway: an oven.

Justified exceptions

Of course, there is a sensible use of this box during printing for very moisture-sensitive materials. Eryone and other manufacturers offer dryer boxes with an outlet to which you can connect a PTFE hose.

This is then led to the filament sensor or the extruder. Better printers have an integrated connection for the hose, but there are also hose sets with connectors.

Alternatives

What if the oven is hogged or the family members find it unhealthy to dry plastic in the oven?

As mentioned, the good old dehydrator is a good alternative to the expensive drying boxes and the oven. Very popular in maker circles are the (round) dehydrators from Ambiano (Aldi) and Silvercrest (Lidl). There are many modifications for these appliances on Thingiverse (Ambiano and Silvercrest) that you can print out yourself.

For temperature and success control, there are the popular thermo-/hygrometers from Bresser. There is also a smilie grinning at you in the display. If it looks sad, the filament is slowly drying out. 🙂 Very likeable.

My solution

Drying

Of course, vacuuming damp filament is pointless. Not even with a whole bunch of silica gel bags, because that is far too weakly hygroscopic to seriously draw moisture out of the filament.

I dry the filament in the oven with circulating air (“Circotherm”) at 50 to 70 degrees, depending on the filament. PLA at 50 to 60 degrees, TPU and PETG at 70 degrees. It shouldn’t be more than 70 degrees, otherwise you’ll end up with a big colourful plastic block in the oven.

“PLA is not hygroscopic after all!” Yes, but after a few years, PLA becomes brittle due to ageing and (very low) moisture absorption. A “sauna session” like this also freshens up PLA.

In the oven, put the rack on the lowest shelf, stack the filament rolls on it, close the oven door, but put a cooking spoon in the door, for example, so that the moisture can escape.

Bake the whole thing for a few hours. Then vacuum seal the filament rolls.

Vacuuming

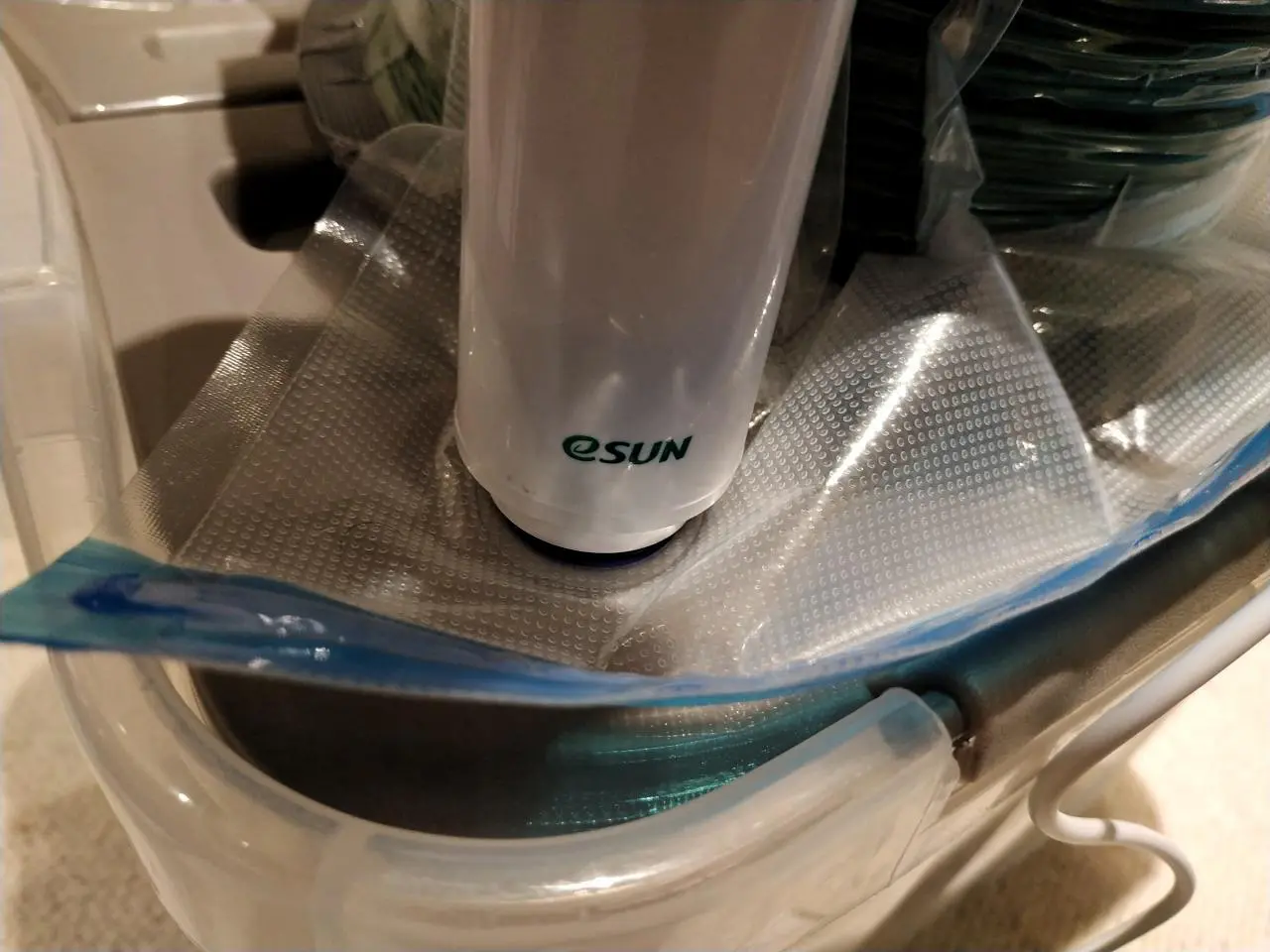

On Amazon, there is a vacuuming set from eSun with 10 bags, some odds, but also a USB vacuum pump. I didn’t want one of those dizzy hand pumps that you only tire yourself out with.

There’s also the set with a manual pump, but that’s about one (!) euro cheaper at 17 EUR. That makes no sense.

So I slipped big A almost 18 euros over the virtual counter, and they threw a package in my letterbox in return.

Uiiiii … A pro kit for the pro printer. Awesome!

But what’s in it?

- 10 vacuum bags

- 10 spare sticker valves

- 10 silica gel bags

- 2 pressure clamps

- 1 USB vacuum pump

The small blue bags contain small porous granules of silica gel, a synthetic silicate mineral. Silica gel has a high capacity to absorb water vapour without itself becoming liquid, as is the case with typical room dehumidifiers. It is considered non-toxic.

“But Hessi, there are also the bags as “original” for food! And there are also the bags for clothes that you can empty with a standard hoover!” — Yes, sure, but the grocery bags are not cheaper, they cost the same and usually, there are also different sizes in the set, but we only need one of them.

The bags to hoover typically have the suction nozzle in a place that is inconvenient if you want to vacuum filament. And I would rather not carry the hoover around every time.

And of course, the pump. This one is missing a power supply, but everyone should have that at home.

Compression bag

Yes, we already know these bags. They are available for food or for clothes that need to be stored in a space-saving and dry way.

One side of the bags is corrugated on the inside, these are air channels so that the air can be extracted.

We put the roll with the dried filament into one of the bags. The smooth side goes on top.

And throwing another bag of silica gel behind it.

The bag is closed. Either we press the two sealing bars together with our fingers or one of the enclosed press-on clips.

Now we pump the air out of the bag. To achieve this, place the bag on a flat surface and hold the pump medium firmly on the blue valve. If we press too hard, no air will come out, if we press too lightly, the pump will draw in secondary air.

There is a switch on the top of the pump, we press this and the air is sucked out of the bag.

After about thirty seconds, we see success. There is a crackling sound, the bag tightens around the roll and if we are not careful now we bend the roll too much. The pump does not seem to switch off automatically.

I throw all the rolls into a storage box from “Action”, so the bags don’t get damaged and pull air.

More bags?

Available here.

Which filaments are not hygroscopic?

Of course, I still owe you this list: Filaments that are considered to be low hygroscopic.

- PLA (polylactide)

- ABS (acrylonitrile butadiene styrene)

- HIPS (high impact polystyrene)

- CPE (ethylene-propylene copolymer)

- TPE (thermoplastic elastomer)

These filaments can absorb up to 0.5% of their weight in moisture. This is significantly less than hygroscopic filaments, which can absorb up to 10% or more moisture.

The low hygroscopicity of these filaments means that they are less prone to problems such as nozzle clogging, uneven surfaces and reduced strength. They can therefore (usually!) be used without prior drying.

However, it is of course always advisable to store the filaments in a dry place to maintain quality.